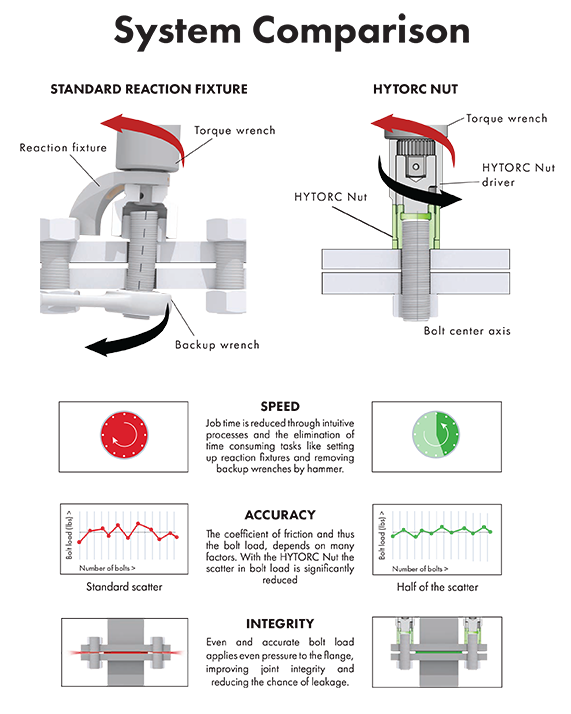

The patented HYTORC Nut system provides optimum joint integrity for critical applications requiring the highest level of bolt load control. This three-piece fastener applies pure tension to the bolt to prevent thread damage and ensure bolt load accuracy. Available in a variety of materials to suit all applications from extreme temperatures to harsh climates. So, here are 3 reasons to use the Hytorc Nut for your industrial bolting jobs. For any questions about your industrial bolting applications, engineering or simply to speak to an expert CONTACT US

01. ACCURACY OF THE CALIBRATED LOAD

No other bolting system offers the same level of repeatable precision, ensuring equal bolt loading to eliminate joint failures and unintentional nut loosening.

02. TOOL LONGEVITY

Other bolting systems place the reaction arm and square drive on opposite sides of the tool, generating high stresses in the tool body, which can lead to failure over time. The HYTORC nut places the action and reaction on the square drive axis to eliminate the majority of internal stresses and increase the life of your tools.

03. “DAMAGE-FREE” REMOVAL

The HYTORC Nut is the only fastener that can guarantee the elimination of seized or damaged threads during installation and removal. These fasteners have been installed on a variety of high temperature applications for ten years or more, and have been removed without damaging the bolts, saving you a lot of money by eliminating the need for bolt replacement. Below you can see how the Hytorc Nut works. Or DOWNLOAD the HYTORC NUT Operation Manual by clicking on the red link.

Regardez la comparaison entre l’utilisation d’écrou traditionnel et le Hytorc Nut

HYTORC NUT: Demonstration of the nut system

. https://www.youtube.com/watch?v=zENWAYzQPx8