The Hytorc ICE tool is the most advanced innovative (and patented) torque tool on the industrial bolting market. ICE is fully dedicated to the highest industry standard torque and tension applications. Whatever your industry: transportation, mining, forestry, paper mills, industrial engineering, petrochemicals, steel industries, etc. ICE is the ideal solution to reduce your labor costs, reduce the risk of accidents, and increase the efficiency of your bolting work.

Below you can check the operation mode of ICE tool. Or Download HYTORC ICE tool operation manual by clicking the red link.

View the Conversion Torque Charts for the Hytorc ICE tool

(Click on the links to download the PDFs)

TC-ICE – 0.7

TC-ICE – 1

TC-ICE – 3

TC-ICE – 5

Using the HYTORC ICE™ Square Drive Torque Wrench

HYTORC Hands-Free Lock (ICE with HYTORC Washers)

HYTORC ICE is the world’s only hydraulic bolting system with an integrated automatic release system that prevents tool jamming. The HYTORC Slider Machine is shown here for hands-free operation with no external feedback – the safest and most accurate bolting method available today.

Hytorc ICE: the highly flexible pivoting tool

Animation of the Hytorc ICE tool screwdriving system

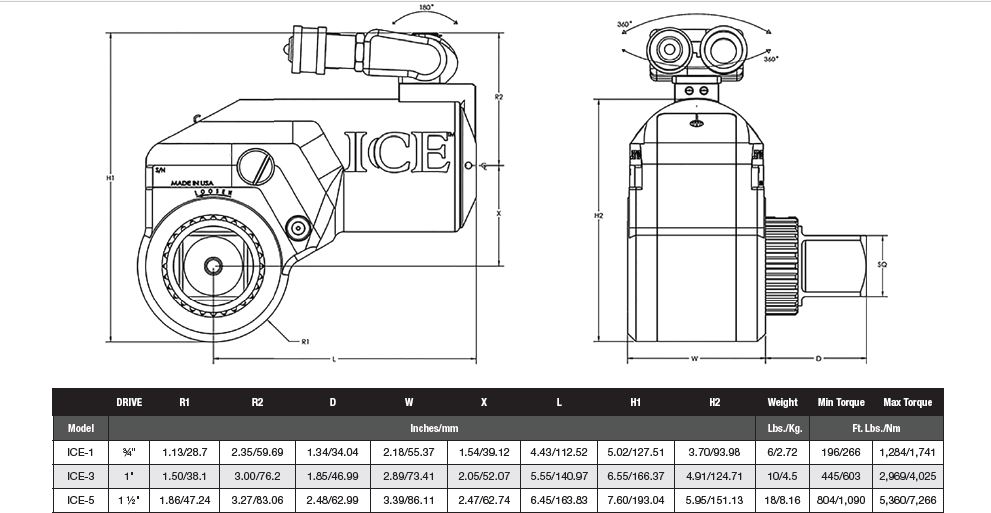

Hytorc ICE Industrial Bolting Tool Dimension and Chart

Hytorc ICE Tool Diagnosis and Troubleshooting (troubleshooting)

Before testing hydraulic torque wrenches. A visual inspection should be done. The visual inspection should include.

1. Coupleurs fissurés, tordus ou endommagés.

2. Swivel assembly

Cracked swivel block

Loose swivel assembly

A swivel post retaining ring is attached

3. Loose cap

4. Cracked or damaged case

When testing hydraulic torque wrenches. Make sure the pump is working properly and is set to 10,000 PSI before connecting the tool. Connect the tool to the hose and test it using the remote pump. ADVANCE and WITHDRAW the tool several times. Make sure the tool operates properly and the pump pressure increases to 10,000 PSI / 700 BAR in the ADVANCE position.

If the tool does not advance or retract. Check the following.

– Couplers are loose or damaged.

– Tighten and/or replace couplers.

– Ratchet

Replace the ratchet if the teeth are stripped, missing or damaged.

Ratchet Assembly

Check the ratchet springs for damage.

Inspect the motor ratchet for damage.

The tool does not generate 10,000 PSI in the ADVANCE position and no external leaks occur. The tool has an internal leak. The internal leaks are in two areas, the swivel assembly and the cylinder.

1 – Swivel Assembly – Tool does not produce more than 2000 PSI

Replace damaged swivel joints.

Inspect the swivel post for wear or damage.

Inspect the swivel block for damage.

2- Cylinder – The tool will not build more than 6000 to 7000 PSI

Check the piston and cylinder O-ring for wear or damage.

Inspect the piston to ensure it is not worn or damaged.

Inspect the cylinder wall for excessive wear.

The tool has an external leak.

1 – Swivel Assembly

Bent or broken couplers.

Worn and/or damaged seals.

Cracked or damaged swivel block.

Damaged swivel post.

2 – Cylinder

Worn and/or damaged seals.

Loose end cap

Worn and/or damaged piston assembly.

Damaged housing.

If the square drive of the tool oscillates in both directions. Check the following points.

1 – Lever Assembly

Lever mounting screws are overtightened.

Cracked and/or damaged levers.

2 – Reaction Pawl Assembly

Damaged reaction pawl spring.

Damaged reaction claw.

3 – Ratchet

Replace the ratchet if the teeth are stripped, missing or damaged.

More information about the Hytorc ICE Bolting Tool:

Animation on the assembly of the ICE tool