ARE YOU PLANNING A MAINTENANCE SHUTDOWN?

LISTEN TO THIS!

CONTROLLED CLAMPING: SAFETY, EFFICIENCY, PROFITABILITY!

Our team of industrial torque specialists is here to support you. Whether it’s the choice of equipment, the tightening procedure to be applied or the execution of bolting work, we’re here to help you.

Industrial Torque: reduce the risk of injury while increasing efficiency and profitability!

We work closely with engineering departments, operations managers, project managers, site foremen, pipe fitters, boilermakers, heavy equipment mechanics and field technicians.

This support at all levels enables us to ensure consistency and quality in all controlled clamping work. Our aim is always to reduce the risk of accidents and injuries, improve overall safety and increase efficiency. And, of course, to reduce costs and increase the profitability of all bolting operations.

Controlled clamping for all types of projects!

We can also work upstream on your projects in partnership with engineering departments to plan the integration of bolting work into the overall execution of major industrial projects. (IIF, infrastructure development, plant layout expansions, addition of new equipment, etc.).

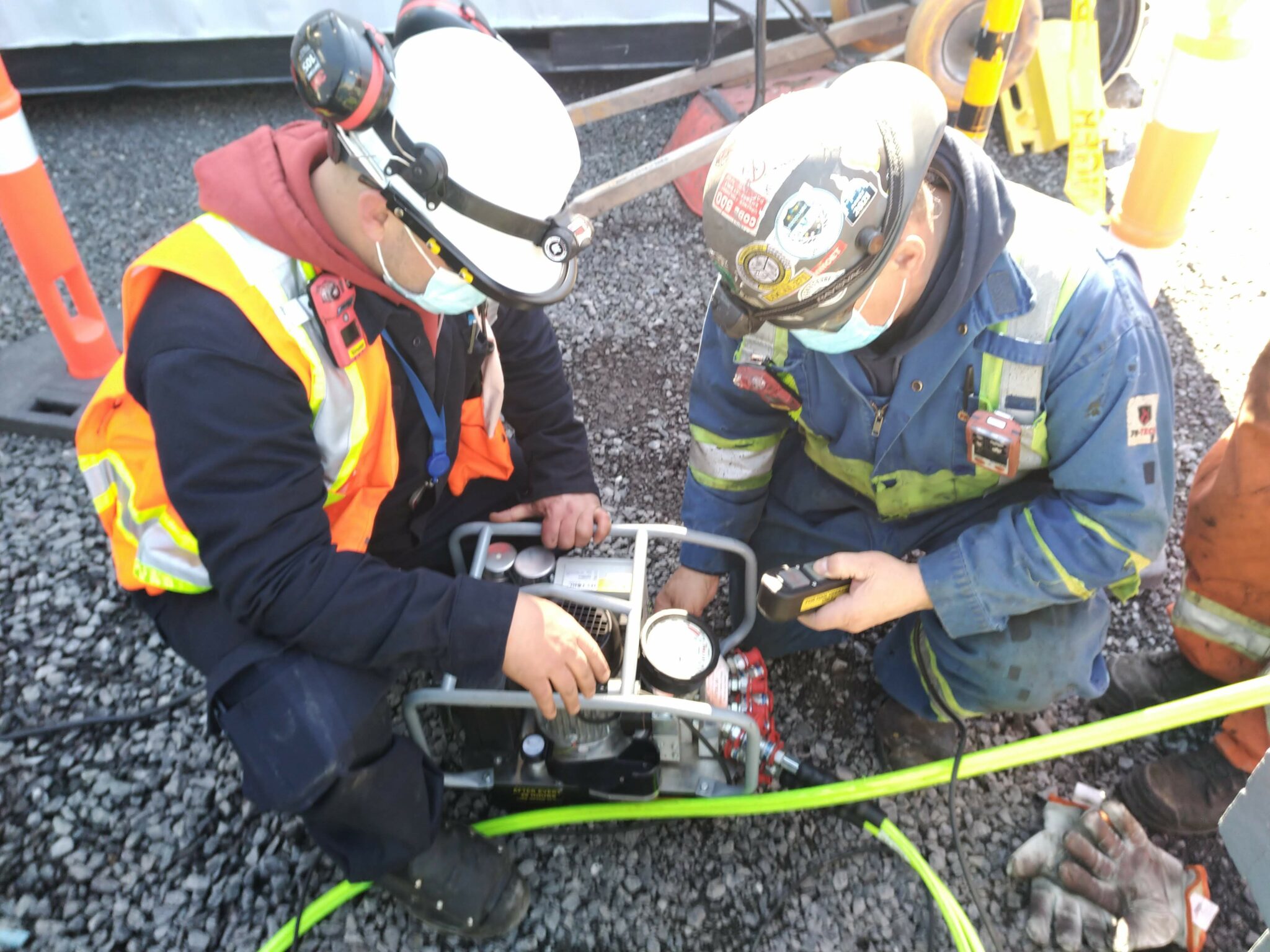

Our aim is always to find the best clamping solutions, whatever your industry. Whether you’re working in a refinery, a pulp and paper mill, a mine, or tightening bolts on trucks or heavy vehicles, we always have the right solution.

We offer you the tools of choice for heavy-duty industrial bolting.

Your project may require, for example, hydraulic tools to achieve greater torque power.

In some cases, battery-powered tools such as Lithium can be very practical. Especially when working in tight or hard-to-reach places. Some jobs may require pneumatic tools instead…

In short, every controlled clamping application deserves the right tool, but in any case, at COFA we’ll have the right tool for your project! If you have any questions about your project :

CALL US!

Turnkey torque project.

Not only do we supply professional torque tools, we also provide expert advice and skilled manpower to ensure that industrial bolting work is carried out safely and correctly.

Our turnkey project management frees your mind! Our goal is to ensure that your project is executed to the highest industry standards.

Controlled clamping experts and on-site training

After many years of experience, we know that investing in training is essential. A well-trained worker increases profitability, safety and efficiency!

Controlled clamping training is provided on site at the start of the job. In addition, supervision is provided by the Cofa team during the work if you wish. Since 2020, we’ve also been offering video tutorials and training to facilitate distance learning.

We believe that continuous training is essential! Bolting techniques and technologies are constantly evolving… And it’s important to keep your knowledge up to date!

Professional torque tools.

As you now know, we can assist and train your employees in the use ofHytorc tools. Que ce soit pour un achat ou une location d’outil ponctuelle… Nos experts vont vous suggérer le meilleur outil pour le travail à effectuer.

You can rent professional torque tools online. You can do the work yourself if you have qualified people in-house. And, if you need on-site support, our torque control experts will be on hand!

Stay tuned for the continuation of our series on industrial bolting (controlled tightening).

Now that you know how the COFA team can support you in the planning and execution of your work, we’ll show you how it’s done in the field. And we’ve taken a very telling example… Maintenance shutdown!

In the industrial sector, maintenance shutdowns cost the company hundreds of thousands of dollars. This is why optimizing time and work efficiency counts for a lot. But, bolting is not only done during a maintenance shutdown… We can optimize each bolting intervention. In some cases, if we only look at the level of controlled tightening work… A well-applied procedure can represent millions of dollars in savings for the company! And this, in just one year!

How to organize bolting work during a maintenance shutdown?

We’ll look at this together in the next article. We’ll also look at how to determine the efficiency gains you can achieve by using the HYTORC parallel seal.

You want to CALCULATE YOUR TIME SAVINGS on a bolting job?

We’ll be talking more about this (with supporting evidence) in the rest of this series too. In the meantime, if you want to know

how much time you could save on your project:

CALL US!

You can follow all COFA Hytorc’s activities on Linkedin

#COFA #COFAHytorc #bolting #industrialbolting #boulonnage #industriel #sécurité #safécautravail #CSSTprevention #tension #Hytorc #superdouille #green #socket #highpressuresockets #greensocket #hytorctools #Ecolinesocket #socketecologique #socketeconomique #Hytorcway #boltingsolutions #boulonnagesolutions #torque #torquesolutions #hightorque #torquewrench #hightorquewrench #douilledurable #DouilleHautRendement #hytorcmanualtorque #serragecontrolé #boulonnage #couple #cledynamometrique #torquemanuel #tension #lubrification #lubrifiantsindustriels #locationtorque #locationdetorque #locationOutilindustriel #SuperSocket