What exactly is a torque wrench?

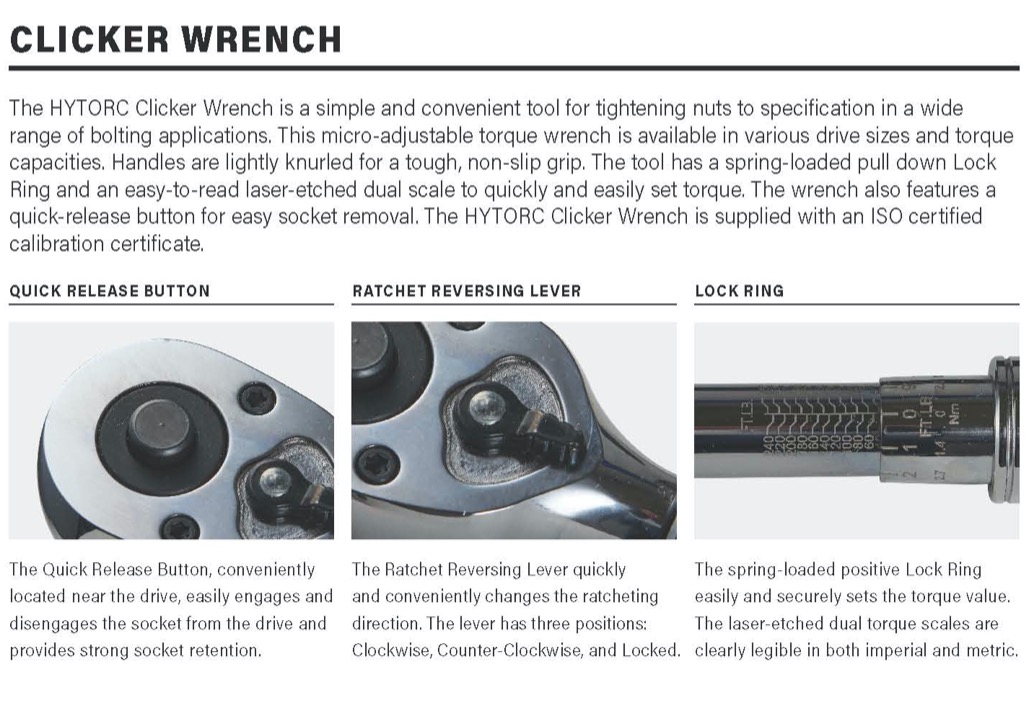

In this article, theCOFA team explains everything you need to know about choosing, maintaining, adjusting and using a torque wrench for optimum bolting results. Visit torque wrench (or clicker wrench), is a tool that tightens nuts (bolting) or screws by applying controlled tension or force.

For smaller torque requirements, you can now buy torque wrenches from COFA. You can also rent or buy torque wrenches with more power for industrial-grade tightening.

Whether for industrial bolting or other applications, torque is composed of two values: the length of the lever and the force applied at the end of the lever (see image below).

If you have any questions or require further information, please click below:

For bolting In heavy industrial applications in Quebec, torque wrench grade and power are measured in Nm (Newton meters) or lbs/ft (pound feet). There are several types of torque wrench, depending on the application. The main types are: circular dial, direct-reading dial, spring-calibrated, vernier-adjustable or twist-grip.

A few charts to help you choose your torque wrench.

Select a torque wrench model.

2 factors in choosing the right clicker wrench

Depending on tightening torque

The torque of a torque wrench always depends on the type of nut, bolt or screw you need to tighten.

For example, a torque of 100lbs/ft may be suitable for mechanical assembly cover bolts. But, for example, to tighten a truck wheel (e.g. 53′ transport), a torque of around 500lbs/ft is required. The same applies to engine mounting bolts.

Depending on square drive dimensions

This is an important point to bear in mind when purchasing your torque wrench. Each type of square drive has different dimensions in inches, 1/4 inch , 3/8 inch , 1/2 inch for the standard square and 3/4 inch for the stronger square.

So when it comes to choosing the right square drive, your choice will depend on the force you want to apply and the square drive that goes with it.

Why buy a torque wrench?

The clicker wrench: a highly effective and precise tool, if used properly

A torque wrench can be a very effective and precise tool for tightening a screw, a nut or a mechanical part, for example.

Using this tool prevents you from over- or under-tightening. Consequently, the torque wrench can help you avoid the 2 main causes of broken or unscrewed bolts. All you need to do is determine the torque you want to use and stop when it’s reached.

Save time and tightening precision

Unlike a conventional wrench, a torque wrench has a ratchet that enables you to tighten the nut completely without having to remove your wrench each time.

It’s also an easy-to-use tool with an ergonomic handle. You don’t need to exert much force to tighten your nuts or bolts. And even better, you limit the problems caused by inaccurate tightening. .

The 4 main types of torque wrench

1. Dial gauge torque wrench

This is the simplest and certainly the most popular model. The circular dial wrench is efficient and affordable, but its accuracy is questionable.

2. The vernier-adjustable model

This model is very similar to the circular dial wrench, but can be used for easier torque adjustment using a conventional or digital vernier.

This type of key features a dual-reading mode (book/foot).

3. breaker-type torque wrench

The calibrated spring model much appreciated by tire chekers.

It’s a calibrated spring-loaded torque ratchet that automatically releases and resets. It also features a square drive for sockets.

4. Wrench wrench (most commonly used)

As the name suggests, it’s a wrench with a revolving handle. This is currently the most economical model.

It’s aneasy-to-use tool, with torque values printed on the handle. This type of wrench is particularly useful for low torque applications.

How much does a manual torque wrench cost?

The price of a torque wrench varies according to its torque capacity, the accessories included and, of course, the quality of its materials.

This usually ranges from $200 to $1,000.

For industrial bolting work, There are hydraulic, pneumatic and battery-powered wrenches for high torque applications, costing upwards of $80,000. In all cases, opt for torque tools (controlled tightening) designed by specialist brands such as HYTORC, COFA or HYTORC.

How does a torque wrench adjust?

Before using a torque wrench, you need to know how to set it up properly. To begin with, you need to know the torque value. It’s very important to tighten the nut to the right value, so that it’s functional and won’t break. To find out the right torque for the type of part you’re tightening, such as a lamp post anchor or motor base, you need to follow the manufacturer’s instructions. Alternatively, you can follow the norms for tightening a bolt to an average of 50% to 65% of its yield strength in the class concerned.

Basically, you set the torque, adjust it, and click! (see the quickstart guide to our new models here)

Torque wrenches: How to use them?

Torque wrenches are easy enough to use. Virtually anyone can use them to tighten a screw or bolt to the correct torque. Once you’ve selected the torque, lock the knob so that the tightening value can’t change while you’re tightening. Install the socket on your torque wrench and lock it in place.

Tighten gradually and stop as soon as the system tells you that you’ve reached the right value. Gentlemen, we know it’s tempting, but try to avoid adding a little more, as you risk breaking your bolt or damaging your tool (lol).

It should be noted that a torque wrench must be calibrated periodically, every 6 to 12 months. To achieve this, contact cofa.ca

#couple #cledynamometrique #torquemanuel #tension #lubrification #lubrifiantsindustriels #locationtorque #locationdetorque #locationOutilindustriel #SuperSocket #COFA #COFAHytorc #bolting #industrialbolting #boulonnage #industriel #sécurité #sécuritéautravail #CSSTprevention #tension #Hytorc #superdouille #green #socket #highpressuresockets #greensocket #hytorctools #Ecolinesocket #socketecologique #socketeconomique #Hytorcway #boltingsolutions #boulonnagesolutions #torque #torquesolutions #hightorque #torquewrench #hightorquewrench #douilledurable #DouilleHautRendement #hytorcmanualtorque

Torque turnkey project.

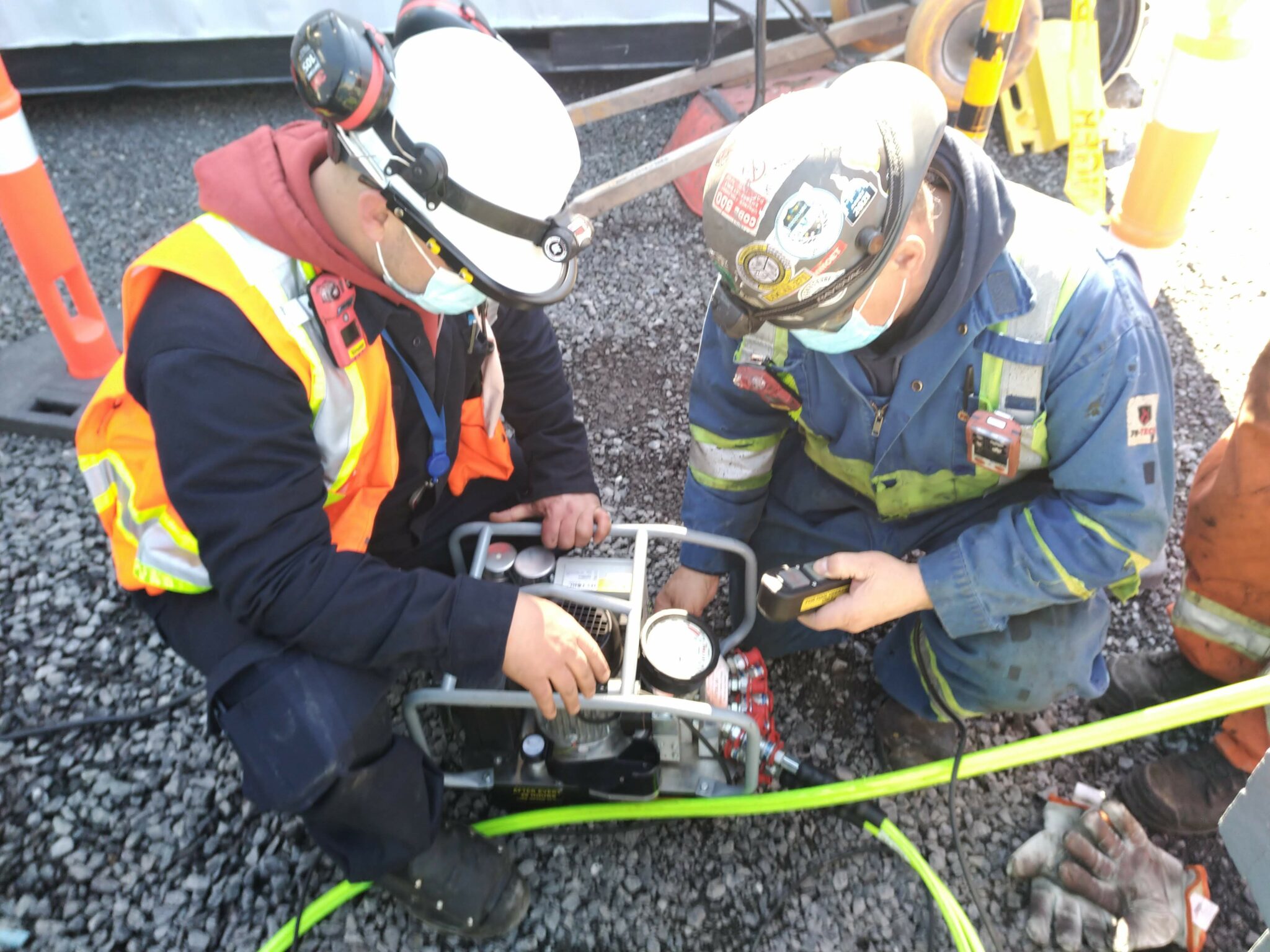

Not only do we supply professional torque tools, we also provide expert advice and skilled manpower to ensure that your industrial bolting work is carried out safely and correctly.

Our "turnkey" project management puts your mind at ease! Our goal is to ensure that your project is carried out to the highest industry standards.

Controlled clamping experts and on-site training

After many years of experience, we know that investing in training is essential. A well-trained worker increases profitability, safety and efficiency!

Controlled clamping training is provided on site at the start of the job. In addition, supervision is provided by the Cofa team during the work if you wish. Since 2020, we've also been offering video tutorials and training to facilitate distance learning.

We believe that continuous training is essential! Bolting techniques and technologies are constantly evolving... And it's important to keep your knowledge up to date!

Professional hydraulic torque tools.

As you now know, we can assist and train your employees in the use ofHytorc tools. Que ce soit pour un achat ou une location d'outil ponctuelle... Nos experts vont vous suggérer le meilleur outil pour le travail à effectuer.

Please note that you can rent professional torque tools online. You can do the work yourself if you have qualified people in-house. And, if you need on-site support, our controlled tightening experts will be there!